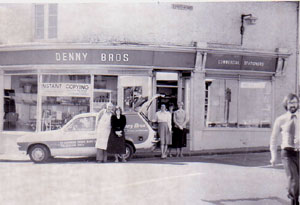

Corporate transport 1950s

|

Bury St Edmunds Printing Industry

History of Denny Brothers Ltd

(Please note that some earlier dates here are from memory and may require verification)

| 1945 |

The Denny family have been in Suffolk for centuries, and in 1945 one branch of the family were living at 57 Fornham Road, Bury St Edmunds. There were four sons named Douglas, Russell, Haig and Nigel and a daughter named Heather. It was to be Douglas and Russell Denny who would be the founders of Denny Brothers, the printers, which was to become an international firm still based in Bury St Edmunds today.

|

|

The original 1930s Harrild Press

|

|

blank |

In the days before E-Bay and the internet, the Exchange and Mart weekly periodical was the best place to look for bargains, and four years earlier, Russell had found an advertisement for the sale of a 1930s Harrild and Sons 11x7 inch platen, hand fed printing press with accompanying cases of type. A small independent printer in the north of England wanted to retire and sell off his used press. Russell was only 14 years old at the time, but he travelled up to view the machine, and was able to afford to buy it and pay to have it transported back to Fornham Road. It was duly installed in the garden shed off Sandy Lane.

In 1945, after being released from the Royal Navy, Douglas Denny returned to Bury St Edmunds, his home town, to undertake a stint with the Royal Observer Corps. Before 1940, Douglas, born in 1923, had been a trainee working in the Co-Operative bakery in Bury St Edmunds. His younger brother, Russell, meanwhile had been apprenticed to a printer, and was now awaiting his own call-up papers for National Service. Russell worked at Paul and Matthews, the general printers, who at that time were based in the Buttermarket, with premises which extended through into Skinner Street.

After hearing about the printing business from Russell, Douglas decided that he liked the idea of being a printer better than the thought of returning to a Baker's trade.

With the post-war winding down of the Observer Corps, Douglas was granted three months paid leave as a preparation for the return to civilian life. During this time he learned to operate Russell's machine, and came to believe that he could make a living in the printing business.

As Russell was soon going to be away for the two years of National Service, Douglas offered to buy the machine from him. After discussions, it was decided that the two brothers would go into partnership instead, so that Russell would have a job to return to after National Service.

So the Denny Brothers partnership was formed, and Russell then had to go off to serve his two years as a conscripted National Serviceman from 1945 until 1947.

|

|

Rear of 57 Fornham Road

|

| 1946 |

For two years the Denny Brothers printing partnership operated from a shed in the garden behind number 57 Fornham Road, on the corner of Sandy lane. These houses have since been renumbered, and number 57 is now called number 99. Douglas found that paper was always in short supply after the war, but if he could get supplies of paper stock he could always manage to sell his products.

He printed anything and everything that a small printer could undertake. He printed letterheads and invoice forms, purchase orders and delivery notes. He tried business cards and wedding invitations. Toys and board games were another experiment, with his own ideas being printed up when orders were short. Stamp albums, and children's drawing and colouring books were all tried. These were sometimes sold from a small stall on Bury St Edmunds market by the brothers and any family members who could be pressed into service.

|

|

Typecases for the Harrild Press

|

|

blank |

Printing at this time was done by assembling metal type into the required words, in a mirror image of the final type, and formatting the layout within metal frames. The frame containing typematter is called a ‘forme’. This process is called "letterpress", as opposed to "litho" or lithographic printing where an etched plate is produced. The Harrild press could print on paper stock up to 11 inches by 7 inches, limiting the work that could be undertaken. Another limitation was the amount of type available. For each job the type had to be built up from the individual letters, and when the job was printed, the type had to be disassembled and the individual letters replaced in the right compartment. Running out of type was a frequent problem as the need to get on to the next job might mean there was no time to "dis" the last job. "Dissing" was the term for breaking down the old job and distributing the letters back to the right compartment.

The illustration shows the cases of type used on the Harrild Press. Each drawer contained one size, (say 6 or 8 point etc) of each typeface or fount (eg Times ), and "case", (uppercase or lowercase). (In those days the word font was always spelled fount, but this would later became Americanised to font when word processing and computerisation arrived.) Bold or italic versions of each fount required another drawerful of type. Each letter set was carefully kept within its own compartment of the drawer.

|

|

Site of Works in Tayfen Road

|

| 1947 |

In 1947, Russell returned from National Service, and the two brothers embarked upon a brave expansion into owning their own premises. They approached the bank to borrow what was equivalent to two year's turnover to purchase premises in Tayfen Road. They bought a site in Tayfen Road, about opposite to where the Tayfen Autopoint is today, (2012), made up of buildings and a yard. They had to borrow £1,200, a massive amount for a small firm at the time. The brothers were confident that they could sell their products and meet their loan repayments.

The yard was let to a local builder, C J Allen Ltd, while Denny Brothers acquired more equipment and now employed two apprentices to help with production. The yard is now a used car lot, but the original buildings have been demolished and partly replaced.

The Tayfen Road site would be their business home for thirteen years, until 1960.

The Exchange and Mart weekly periodical became their main outlet for their advertising as it reached a national audience at minimal cost. It soon proved its worth, with jobs arriving from far afield.

|

|

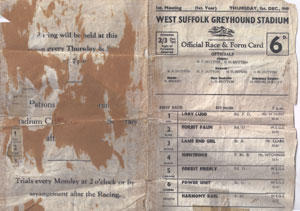

The first WSGS Race Card

|

| 1949 |

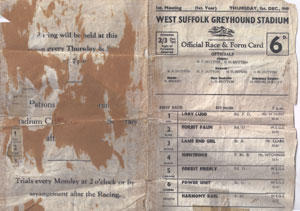

During 1949 the Dennys heard that a greyhound racing track was being planned a couple of hundred yards away from their premises in Tayfen Road. They expressed their interest in supplying the race cards and programmes that might be required, but heard nothing more until the morning of December 1st, 1949. One of the Dutton brothers, (called Joby and Douglas), arrived at their works with a handwritten list of dogs and races and requested 1,000 printed copies for 7pm that evening! With no formats agreed and nothing in place, the Denny brothers had to work flat out to design, typeset, print, fold and deliver the race cards. They were so short of time that they finally had to be delivered in relays as each batch came off the old hand fed, foot operated Harrild Press.

A rather dilapidated race card survives from that first day and is shown here. "Denny Bros., Printers, Bury St Edmund's" can be seen at the foot of the back cover if you click on the thumbnail to get a larger view.

The West Suffolk Greyhound Stadium became a regular customer for the next 20 years, when the printing contract would end as abruptly and with as little ceremony as it started. Such was the pressure of time and accuracy of these twice weekly runs of programmes for six dogs and six races on Thurdays and Saturdays that, of all the jobs they did, Russell Denny said he lost most sleep over this one.

|

|

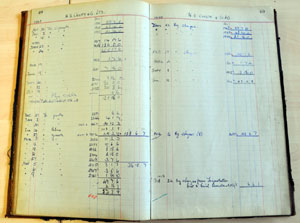

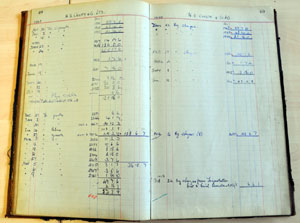

Sales ledger - H B Crispy account

|

|

blank |

Around this time there were still shortages of basic materials but there were possibilities for small businesses to find a niche. A job which came in around November, 1949 was from a Bury St Edmunds man who wanted to try setting up as a potato crisp manufacturer, trading as H B Crispy and Co Ltd, of 7 Ipswich Street. Potatoes were not on ration and local spuds were available. He required hundreds of grease proof bags to be printed up with his name and an attractive design to contain his products. Nobody can nowadays remember these crisps, but the business survived for a while as a local brand. He was up against Smith's Crisps, which had been going in London since 1920, while Walker's Crisps had just started with the same idea in Leicester in 1948. Golden Wonder had been going in Scotland since 1947.

Crispy crisps struggled on until it collapsed in March 1951, and in October 1952, Denny Brothers received a final payout from the liquidators of £6.6s.1d. This left a loss to the Denny Brothers of £45.17s.8.

|

| 1954 |

By this time the sign above the Tayfen Works read, "Denny Brothers General Printers and Paper Bag Merchants". The brothers had worked out a system to make carrier bags for local shops and other customers. From printing the customer's logo and shop details on paper stock, forming the bag and adding a string handle, they manufactured the whole process. This was a valuable extension to the work they could undertake.

|

|

St Andrews Hall with tall gable end (2012) |

| 1960 |

In 1960 the firm of Denny Brothers decided that they needed more room to expand their printing business. The premises in Tayfen Road, home to the firm since 1947, were sold off, the building then becoming the Post Office Social Club. Eventually the original Denny Brothers building was demolished.

Before disposing of Tayfen Road they purchased number 50, St Andrews Street, South. This was an old hall, known as St Andrews Hall, which was, at the time, housing T H Nice's paint spray workshop for their garage and car repair business. The hall had a colourful history, as it had narrowly avoided being burnt down during a Zeppelin raid in April, 1915. Although the adjacent premises on the corner of Kings Road had been badly damaged and the three floor structure rebuilt as only two floors, the old hall itself had escaped destruction.

The hall had a very high roof, and in due course the brothers would make extra space by building a first floor into it. An older picture of these premises is shown below at 1962.

|

|

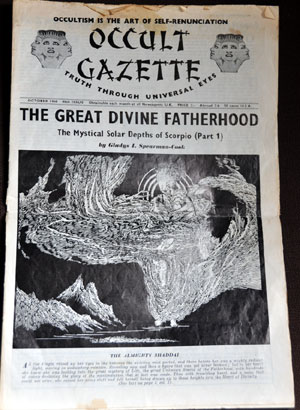

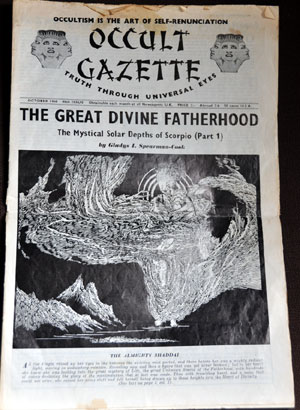

Sample Occult Gazette from 1968

|

|

blank |

Following the move several interesting jobs came along for the firm. The oddest was, perhaps, to print the Occult Gazette for the School of Universal Philosophy and Healing, run by the principal, Mrs Gladys I Spearman-Cook. She had founded the School in Kensington in 1946 following a career as a medium. She required her followers to give up all their wealth to the School when they entered and required them to address her as Zamiar. She claimed to receive instructions from her spirit guide "Ra-Men-Ra."

Mrs Spearman-Cook had answered the Denny's advertisement in either the "Exchange and Mart" or "The Stage", and this contract was to be a long running, and reliable, source of work for the brothers. Other contracts for work from London would follow this one as Denny's became known for being able to handle such a production. The Gazette was the size of a tabloid newspaper, and had 16 pages. At this time the brothers used the services of St Albans Typesetters to produce the type on their Linotype machines. Barry Denny remembers accompanying his father on the evening trips to St Albans to collect the slugs of made-up type, often missing his homework to do so. In fact, at first the job was so large for the small firm that after they printed the pages, they had to be taken to the family home in Severn Road. The reason for this was so that as many family members as available would hand fold and then collate the production ready to return the finished magazines to the factory for collection.

In 2009 Elisabeth Fraser, an editor and author for Jarrold Publishing, wrote a book called "Fragments", in which she described her life in several cults or sects, the first of which was the School of Universal Philosophy and Healing. She recorded how one of her jobs after she joined in 1956 was to undertake all the typing and mailing connected with the Occult Gazette. She described how she and her brothers would take turns, every third month, to collect the printed copies of the Gazette from Bury St Edmunds.

One night her mother and her brother James had gone to Bury as usual to collect the magazines. Elisabeth received a telephone call from a witness to say that their car had turned over near Bury, full of magazines, and her mother was injured. With another brother she left London at 12.30 am to drive to Bury, finding her brother still with the car, but in a state of shock. All three then went to the hospital to visit their mother. Elisabeth refused to allow doctors to give her mother a lumbar puncture, and she would stay in hospital for six weeks. James was given a sedative for his shock, but after an hour all three returned to the scene, recovered all but a few magazines, and then returned to London, all before dawn the same day. By 5.30 am they joined others in the group to envelope up the magazines ready for posting that evening.

There is a legend within Denny Brothers that following this accident, the driver was given a blood transfusion whilst unconscious. When he later found out about this, he declared that he would die because the sprits were against the giving of blood. The legend states that he subsequently died, but as seen above, Fraser's account does not support this story. She split with Gladys Spearman-Cook in 1963.

At first the Occult Gazette was printed four times a year, but was a monthly by 1965. It was still being printed in 1972, and may by then have become only bi-monthly issue.

|

|

First Heidelberg |

| 1961 |

In 1961 the Brothers purchased their first Heidelberg press. This was the Heidelberg Crown Folio platen model, with automatic feed. Crown folio was a paper size of 10x15 inches, allowing a larger print area than before. Automatic feeding of the next sheet of paper avoided the need to put each sheet into place by hand. This still used the old letterpress system and such machines would continue to find a useful life despite the looming advent of litho printing. This machine is still owned by Denny Brothers, and is shown here with Barry Denny on the Kempson Way factory floor. The "hands off" sign on it shows that modern safety requirements preclude its day to day use nowadays.

Heidelberg Printing Machines AG is a German precision mechanical engineering company with head offices in Heidelberg, in Baden-Württemberg, Germany. The Heidelberg Platen press became the mainstay of British jobbing letterpress printing and many machines still see service today working on jobs that litho or digital machines cannot do, such as odd shapes of stock, numbering, creasing and perforating, for example. Heidelberg would produce its first litho press in 1962.

In 1961 the Heidelberg Company offered new buyers £100 trade-in allowance on their old machine, in this case the Harrild press. Upon discovering from the firm's representative that these old presses were to be destroyed, Douglas Denny asked if he could buy back the Harrild in order for his son Barry to make use of at home. Barry was about 13 at the time, and had been brought up with the smell of printers ink and had helped around the business during holidays and after school. After some discussions the Heidelberg company delivered the press gratis to the Denny home in Severn Road, where it was set up in the shed. While he was still at the King Edward VI Grammar School Barry Denny undertook the printing of programmes from his shed for many of the school's sports days and school plays.

|

|

Denny Brothers St Andrews Street works 1962 |

| 1962 |

The photograph shown here is of the St Andrews Street works and shop in 1962. The people are, from left to right:

- Unknown

- Haig Denny, brother of Russell and Douglas Denny.

- Ron Cockle, who worked for Denny Brothers from the age of 15 to retirement at 65.

- Pat Hannah

- Trevor Smith

- Fred Rowe

- Russell Denny, one of the founders of Denny Brothers.

- Douglas Denny, also one of the founders of the firm.

|

| 1963 |

The larger jobs, such as the Occult Gazette, had meant that the Denny's had needed to outsource the typesetting to St Albans Typesetters in Hertfordshire. This got the job done, but the finished type had to be collected, and it was a considerable drive to reach St Albans on the road system of the time. Thus in 1963 or 1964, the brothers decided to invest in their own Linotype machine. They had used an old model of this at Tayfen Road, which was soon disposed of, because of its shortcomings. This later model proved much better. Linotype machines had earned the description "hot metal printing", because the individual letters of type were cast in molten lead as the operator typed in the copy. In practice a whole line of type would be cast as one "slug". There was no more need to keep cases and cases of type as had been needed in the past, and no more need to carefully replace the letters in the correct case after a print run. The cast "slugs" were used for the print run, and then returned to the machine to be melted down for the next job.

The typesetting machine had been invented in America in the 19th century, but were now built by the Linotype and Machinery Company of Altrincham, founded in 1889.

This heavyweight monster of a machine needed more floorspace than they had available. Russell's answer to this was to have the machine winched up to the ceiling, while he built a first floor into the old St Andrew's Hall to accommodate it. The typesetter was then duly lowered into its new home.

|

|

Kings Road Corner 1915 |

| 1965 |

In 1965 the brothers bought the Old Dairy, which was on the corner of Kings Road. This was adjacent to their premises in St Andrews Hall, and had been a victim of the Zeppelin Raid in 1915 which had required its upper floors to be rebuilt. In fact, the top floor was demolished, and the building repaired as a two storey building, which it remained in 1965, and also to the present day. Gradually the brothers would acquire as many of the neighbouring properties as came on to the market.

In 1965 the Denny Brothers partnership installed their first litho press. This was a Heidelberg Kord, which was one of the first litho presses made by Heidelberg. It was really a traditional style of press converted to work as a litho press, but it soon became a Jack of all Trades at Denny's and in the printing industry in general.

The litho process involved printing from an etched plate rather than printing from a "forme" of individual metal type characters. The litho process had many advantages over letterpress, but the older machines could still cover areas of work unsuited to lithography.

Such new presses were needed in order to keep ahead of the stiff competition from other printers in the town, such as Pawseys, Grooms, Paul and Matthew, and later start-ups like Youngers.

Late in 1965 another significant Denny joined the firm. This was Barry Denny, who was the son of Douglas Denny, and who had just completed his "O" Level examinations at the King Edward VI Grammar School in Bury St Edmunds. He had achieved the number of exam passes necessary to join a printing course at Norwich City College, and became an apprentice printer. He had already been printing programmes for school plays and sports events on his own account in the shed at home using the original Harrild Press. Barry Denny would eventually become Managing Director of the company.

By 1965 the firm was operating four printing presses. These were: - Two Heidelberg platen presses.

- A2 Stop Cylinder press which was used for the speedy runs needed for the West Suffolk Greyhound Stadium work.

- Double Crown, "Miehle" type two revolution cylinder press for posters and large jobs. This American design was built in this country by the Linotype & Machinery company of Altrincham.

There was also a Linotype typesetting machine which set lines of type from liquid lead into solid slugs for use on the presses.

|

| 1967 |

In 1967, number 49 St Andrews Street became available and Denny Brothers bought it. Gradually they were also able to buy number 48, number 47 and 46 over the next few years, consolidating a hold upon the block of buildings around the Kings Road corner.

|

| 1977 |

The year 1977 proved to be highly significant for the Bury St Edmunds printing firm of Denny Brothers. During the 1970s Denny Bros had done a number of printing jobs for Bayer Agro-Chemicals. In 1977 the firm was asked by crop science specialist Bayer if it could develop an information leaflet to place on the outside of a product bag, rather than

placing it loose inside. The printing firm developed and then patented the idea and Fix-a-Form was born by the end of the year. Patent protection was vital to prevent other companies from exploiting the Fix-a-Form idea, and to allow the company to invest heavily in the further development of the product.

Before the invention of Fix-a-Form, Denny Brothers were just one of a large number of printing companies offering a variety of printed products to customers. Now they had a unique product to sell.

|

|

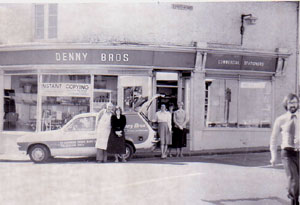

Kings Road shop 1978 |

| 1978 |

This picture shows the shop in St Andrews Street and Kings Road as it appeared in 1978. Click to see a larger picture and a bearded Barry Denny crossing the road.

The people shown are, from left to right:

- Tom Thorne, by the van.

- Vanessa Clarke, by the van.

- Grace Denny, married to Douglas, and mother of Barry Denny.

- Unknown

- Mandy Block

- Barry Denny, crossing the road.

The sign shows that the firm had entered the market to sell commercial stationery and although this continued to generate profitable business, the Fix-a-Form product would generate the real growth in the company. Grace Denny would continue to manage the stationery part of the business after the printing work moved out to new premises. She had to contend with increasing levels of competition from larger suppliers.

|

| 1980 |

It was by no means certain that Fix-a-Form would catch on, and so the Denny brothers continued to try developing and producing their own products, one of which was to make sets of playing cards.

|

|

Fix a Form logo |

| 1982 |

After the development of Fix-a-Form, Denny Brothers went all out to exploit the new product, finding new uses and outlets for its use. However, they realised that in order to exploit overseas markets a new approach was required. In 1982 the firm established Fix-a-Form International as a separate company within the Denny Brothers Group. Its purpose was to begin the manufacture of the machinery required to produce the new products, so as to license Fix-a-Form's production to other companies abroad, including the supply of the necessary machinery.

|

|

The factory in Boby's old building

|

|

blank |

With the expansion of business the firm was always on the look out for new premises, and in 1982 they took out a lease on the old Robert Boby Office block on St Andrews Street, South, in Bury St Edmunds. This gave much more space to hold the growing printing business and all the associated folding, stapling and glueing equipment needed for the new products.

At around this time it was also decided to try a new venture into the art print market. Some paintings were purchased with the intention of producing art prints for sale to the trade and direct to the public. Seeking an artistic sounding name for the new project they adopted the maiden name of Barry Denny's grandmother, and Ottewill Art was launched. A small gallery was created in the St Andrews Street premises to display the works, and members of the public who visited also expressed an interest in obtaining art materials as well. Thus began the expansion of Ottewill Art into the field of artists' materials and equipment. Over the years this became a growing trade until Ottewill Art became one of the best artist's shops in the region.

|

|

The Fasson Awards

|

|

1983

|

In 1983 Denny Brothers' Fix-a-Form products received two Fasson Awards for excellence in the field of labelling and packaging. The awards were for Best Innovation, and Company of the Year. These awards put the Bury St Edmunds printers on the map. Fix-Form had been steadily growing and doing well, but these awards put them on the front pages of trade magazines, giving them access to overseas business as well.

The 1980s now produced a period of rapid growth, with the signing of international licensees, and worldwide sales resulted. The first ever licensee to sign-up was based in South Africa and today there are over 20 companies around the world, manufacturing under licence of their patents, trade marks and know-how.

With the company's growth, and the involvement of other family members, it was decided to convert the business from a partnership into a limited company, now known as Denny Brothers Ltd.

|

|

Mrs Thatcher presents award to Douglas Denny

|

| 1984 |

Mrs Thatcher was in her second term as Prime Minister, and was keen to support family businesses, and wanted to be seen to be involved with Europe. On May 21st, 1984 she attended a luncheon at the London Hilton Hotel hosted by the Netherlands British Chamber of Commerce (NBCC).

The occasion was for the presentation of their Anglo-Dutch awards for Enterprise. After some favourable comments about Anglo-Dutch relations at government level, and comments about government deficits, Mrs Thatcher turned to the awards themselves. A few of her comments are shown here:

"Now the Enterprise Award. It is very important because in a free society one relies on the people, the companies of enterprise to produce the standard of living, to produce the goods and the services which the customer wants against the framework of politics which we in Government try to create......

Now of course I am a great believer in free enterprise, a great admirer of its work, of its sense of adventure, of its attention to good design, of its attention to good financial management, of its attention to the human factor in good management between management and workforce in each and every enterprise. And I am also a great supporter of small business. It not only adds greatly to employment, it not only adds greatly to prosperity, but the people who embark on new business and small business add greatly to the kind of character and independence of our free society.

Now Sir James has already told us that we are here for the awards and I know you are very anxious, as I am, to know who has won the awards. You know that there can only be four and I am very pleased that two of them go to small businesses. "

One of these awards went to Denny Brothers of Bury St Edmunds.

On behalf of Denny Brothers, Douglas Denny received the export award from the Prime Minister, Margaret Thatcher, for Anglo Dutch Co-operation and setting up a license agreement with printing company NSD in Holland.

The Netherlands British Chamber of Commerce (NBCC) is a bi-lateral commercial membership organisation with offices in London and Amsterdam, aiming to promote Anglo-Dutch trade and investment.

As an independent membership organisation the NBCC is able to provide small and medium sized companies in Britain, The Netherlands and elsewhere with assistance in expanding their overseas business activities.

The NBCC services include market research, agency/distributor searches, sales support, company formations and other services.

|

|

Anglo-Dutch Award Luncheon

Anglo-Dutch Award Luncheon

|

|

blank |

In May 1984, after receiving an Anglo-Dutch Export Award, presented at a luncheon at the London Hilton Hotel, this picture was taken of representatives of Denny Brothers and business associates. People in the picture are as follows:

Back Row

- Derek Everingham of the Midland Bank;

- Douglas Denny;

- Michael Cooper of Fix-a-Form International.

Mike was the first MD of FFI, and was responsible for establishing the licensee network overseas;

- Ben Kuhne of Dutch firm NSD;

- Barry Denny;

- Susan Denny, wife of Barry;

- Robin Howard, Production Manager at Denny Brothers.

Front Row

- Grace Denny;

- Russell Denny;

- Win Denny, wife of Russell.

With the firm now restructured as a limited company, Douglas Denny became Chairman of the company, and his son, Barry Denny was appointed Managing Director. Both Russell and Douglas now aimed to gradually reduce their workloads while remaining within the company.

|

|

Mildenhall Road factory

Mildenhall Road factory

|

| 1987 |

By 1987 Denny Brothers had been forced to acquire additional small sites to accomodate their growing business. This included a small factory at 2 Greyfriars Road. This fragmentation of operations was always a problem, and a search for new premises had always been a priority.

By 1987 the company's world wide presence and expanding workloads meant that the factories in Kings Road, Greyfriars Road and St Andrews Street could no longer operate efficiently at these high levels of demand. There had been a continuing search for new premises, and in 1987 a brand new factory was completed at Lamdin Road, on the north side of Bury St Edmunds. Denny Brothers soon began to use the address of Mildenhall Road, as the factory fronted on to that road, and the name was much better known than Lamdin Road.

The printing presses were removed for the old Boby's Office block in St Andrews Street, and the lease was given up. All the printing operations were now moved to Mildenhall Road.

|

| 1995 |

The year 1995 was the Golden Jubilee of the foundation of Denny Brothers, printers of Bury St Edmunds. The firm had been founded 50 years earlier, in 1945, by Douglas and Russell Denny. They had started with one old foot operated platen press, bought from the pages of the Exchange and Mart periodical.

|

| 1998 |

After a long period of searching for a new site for their factory, the firm of Denny brothers finally purchased a 6 acre site on the Moreton Hall Industrial Estate, in Kempson Way. This was on a new extension to the Moreton Hall industrial area, and design and construction needed to be of a high order to fit in with modern requirements. The company hoped to get a new factory built within a year or two. Finalising the design and obtaining planning permission would take them another two years.

|

|

Advert for the millenium

|

| 2000 |

By the year 2000 the firm of Denny Brothers had acquired premises nearby to the Mildenhall Road factory, at 3 Lamdin Road, and also built another small factory behind the Red Cross premises at the bottom of Lamdin Road. This was built in conjunction with Abbey Labels which then traded as Abbey Hine.

They were now operating from their main Mildenhall factory together with the three satellite factories at Lamdin Road. This piecemeal development was necessary because of continued demand and the difficulty of finalising a design and obtaining planning permission at the new Moreton Hall site, to meet their requirements.

This advertisement from January, 2000 shows the Denny Brothers logo from the time. It featured a red and blue db design with a chevron roof that was used when at the Mildenhall Road site, which was intended to mimic the architecture of the factory.

By the middle of the year 2000, however, Denny Brothers had finalised their plans for a new factory at Moreton Hall, and obtained the necessary permissions. The contract could now be let to build a thoroughly modern, well designed and purpose built unit for their future production requirements. Building the new factory would take about one year.

|

|

Kempson Way factory |

| 2001 |

By the summer of 2001 the company of Denny Brothers Ltd could move into their £5 million factory at the newly available Kempson Way factory in Bury St Edmunds. This enabled them to bring all the operations of the group under one roof for the first time, including conference facilities which could be hired to outside users when available.

|

|

New corporate logo

|

|

blank |

Before moving in to Kempson Way it was decided to revamp the company logo and adopt a new house style and colours, to give the launch of new premises a professional and modern public relations image.

The new house style was designed by Stephen Jarrold, (now the company Sales Director), to replicate the sweep of the new roof line and was adopted just before the move, in readiness. It replaced the red and blue db design with a chevron roof that was used when at the Mildenhall Road site, which also mimicked the architecture at the time.

|

|

Official Opening, September, 2001

|

|

blank |

The official opening of the factory took place on 21st September, 2001, after the factory was up and running. This plaque and photograph commemorate the occasion, with the opening carried out jointly by the original Denny Brothers, Douglas (on left), and Russell (on right).

The new factory included climate control and other features which enabled the firm to achieve accreditation for compliance with the Pharmaceutical Code of Practice. This was superseded by PS 9000 in 2003. Denny Brothers are now in the transition with BSI to upgrade to PS9001:2011 which should be achieved by October 2012.

|

|

Marmite jar with Fix-a-Form label

|

|

blank |

The climatic controls and managed workflows which were good enough for pharmaceutical purposes were also perfect for the production of labels and printing for the food industry.

|

|

Denny's Corner in 2012 |

| 2004 |

During 2004 Denny Bros were making plans to develop an old garage next to their shop in Kings Road, Bury St Edmunds into three new shops and six new houses in a £1.5 million scheme.

Work on the King's Road site, which will be known as King's Road Mews, was due to begin early in December, 2004 and aimed to be completed by summer 2005.

The Denny Bros Stationery and Ottewill Art shop were unaffected by the development but Sprint Print relocated next door to St Andrew's Street in January 2005.

One of the new shops was used as a bigger Denny Bros shop, while the other two were made available for lease. The new development was designed by Bury St Edmunds-based architects Milburn Leverington and Thurlow and was built by Haymills of Stowmarket. "Denny's Corner" would now extend well up Kings Road, as shown in this view in 2012.

|

|

Willowbridge logo

|

| 2005 |

In order to retain a presence in the lower cost end of the printing market, Denny Brothers acquired Willowbridge Labels in 2005. This firm employed 8 people on the nearby Rougham Industrial Estate. Willowbridge produced a range of roll, sheet and fanfold labels, including a self adhesive range. They served the agricultural, pharmaceutical and food markets which were the same markets that Denny Brothers had achieved such success in.

|

|

British Printing Industry Federation award

|

| 2006 |

In 2006 the firm of Denny Brothers received a BPIF Excellence award as "UK Company of the Year". The British Printing Industry Federation makes such awards annually. The BPIF is the principal business support organisation representing the UK print, printed packaging and graphic communication industry and is one of the country's leading trade associations. It is a not-for-profit-distribution organisation.

|

| 2007 |

During 2007, one of the founders of Denny Brothers, Mr Douglas Denny, died. His son, Barry Denny, had been Managing Director of the Group since 1984, having taken over from Douglas.

Not only did Douglas die, but also his wife Grace, who had played a significant part in the business, particularly by managing the retail stationery business through the 1970s, 80s and 90s. (She is pictured in the photographs for 1978 and 1981). This business still operates from these premises today.

|

|

The Press Room at Kempson Way

|

| 2011 |

During 2011 Denny Brothers began to offer other companies the machine development expertise that had led to its own success. This was a move into consultancy with the added value of design and build capability.

The work would be undertaken by its own engineering wing, Db Engineering, with 30 years’ experience in designing, manufacturing and setting up production machinery who now intended to move into doing development and prototype work for other companies who need sophisticated machines to make their products.

Denny Brothers invented the Fix-a-Form booklet label which it now licences for production in 22 countries. All the machines that produce the labels, found on products from Marmite to weed killer, are designed, manufactured and assembled in-house and installed by Db Engineering staff.

|

|

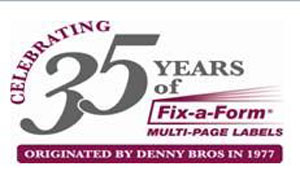

Fix-a-Form's 35th anniversary

|

| 2012 |

In 2012 the firm of Denny Brothers Ltd celebrated the 35th anniversary of the production of their flagship product known as Fix-a-Form. As the patent protection had now expired on the product, the firm now had to ensure that it could compete against new firms adopting the ideas behind Fix-a-Form. Constant innovation in product development and securing new markets was now the firm's priority.

The firm now employed 85 people in the printing company and 15 people in Fix-a-Form International, working on building the machines needed to supply worldwide customers. Willowbridge Labels continue on their existing site at Rougham employing 8 people.

In May 2012 the Denny Bros Group acquired the firm of Ditac Limited, based in Harlow, Essex.

Ditac, established in 1984, supplied specialist labels and systems to a wide range of customers nationally. The Ditac name will be retained.

The company will continue to have a presence in Harlow, but much of the production is being transferred to Willowbridge Labels, operating from Rougham near Bury St Edmunds under the control of managing director Karl Seeley.

In July the company showed that it could still be at the forefront of East Anglian manufacturing. Denny Bros were awarded several honours at this year's Anglian Business Awards.

The company was named Business of the Year at the event, while it was also recognised for its customer service, environmental credentials and as the best family business.

In October, 2012, Russell Denny, the last surviving founder of the firm of Denny Brothers, died after an illness. His brother Douglas had died in 2007. The firm of Denny Brothers continued to be owned and run by their descendants.

|

Prepared for the St Edmundsbury History website

by David Addy, May 24th 2012

RESOURCES USED

Information from Barry Denny, Managing Director of Denny Brothers Ltd

"Legend" reported by Andrew Denny, MD of Fix-a-Form Ltd

West Suffolk Greyhound Stadium information from Martyn Taylor

|